Asphalt Batch Mix Plant Supplier: Pioneering the Future of Road Construction

The demand for efficient and high-quality asphalt batch mix plants has soared in recent years, driven by the growing infrastructure needs worldwide. As an asphalt batch mix plant supplier, Polygon Machinery takes pride in offering state-of-the-art solutions tailored to modern road construction demands. With a commitment to innovation, durability, and efficiency, we stand out as a leading name in the industry.

Understanding Asphalt Batch Mix Plants

An asphalt batch mix plant is a significant component of the construction industry, responsible for producing high-quality asphalt mixtures used in paving roads, highways, and parking lots. These plants combine various ingredients, including aggregates, asphalt binder, and additives, to create durable asphalt mixtures that meet stringent quality standards.

Components of an Asphalt Batch Mix Plant

- Cold Aggregate Supply: This includes a series of bins that store different types of aggregates. These bins ensure precise control over the material's composition.

- Drying Drum: Here, moisture is removed from the aggregates through direct exposure to hot air.

- Mixing Chamber: The dried aggregates are blended with asphalt binder and additives to create a homogenous mix.

- Dust Collection System: Essential for maintaining environmental standards by filtering and recycling dust produced during the mixing process.

- Control System: A computerized control panel that allows operators to monitor and adjust the various parameters of the mixing process.

Why Choose Polygon Machinery as Your Asphalt Batch Mix Plant Supplier?

When selecting an asphalt batch mix plant supplier, it is crucial to consider several factors that contribute to the overall efficiency and effectiveness of your operations. Polygon Machinery excels in the following areas:

1. Unmatched Quality Standards

At Polygon Machinery, we prioritize quality above all else. Our asphalt batch mix plants are built using premium materials and adhere to international quality standards. This ensures that you receive a robust and reliable machine capable of producing high-performance asphalt mixes consistently.

2. Innovative Technology

We integrate cutting-edge technology into our products, providing enhanced features like advanced control systems, energy-efficient processes, and automation capabilities that optimize production and reduce operational costs. By choosing us as your asphalt batch mix plant supplier, you tap into the future of construction technology.

3. Customized Solutions

Understanding that each construction project has unique needs, we offer customized asphalt batch mix plants tailored to your specific requirements. Our experienced engineers work closely with you to design solutions that maximize efficiency and productivity.

4. Comprehensive Support and Service

Our commitment doesn't end with the sale. Polygon Machinery provides extensive support, including installation, training, and maintenance services. Our team is dedicated to ensuring that your plant operates smoothly, minimizing downtime and enhancing productivity.

Applications of Asphalt Batch Mix Plants

Asphalt batch mix plants serve various applications in the construction industry, including:

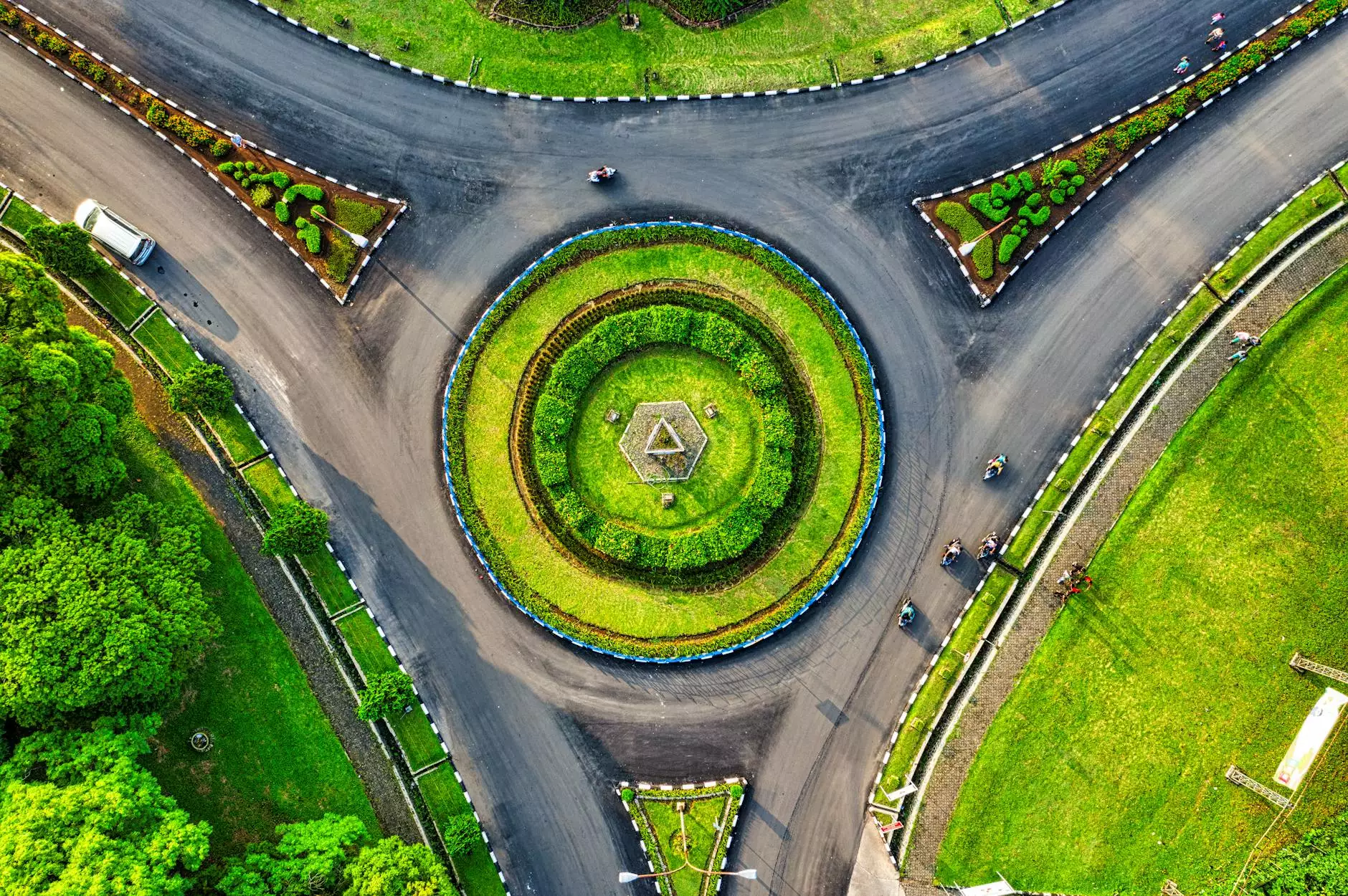

- Road Construction: The primary use of asphalt is for paving roads. The consistency and quality of the asphalt mix are crucial for the longevity and durability of the pavement.

- Highway Projects: Major highways require large volumes of asphalt, and our plants are designed to meet these demands efficiently.

- Airport Runways: Specialized asphalt mixes are used for constructing robust and safe airport runways.

- Commercial Parking Lots: Asphalt is commonly used for paving parking lots due to its durability and cost-effectiveness.

Environmental Considerations

Sustainability is at the forefront of today's construction practices. As an asphalt batch mix plant supplier, Polygon Machinery integrates environmental considerations into our design and production processes:

1. Recycled Asphalt

We promote the use of recycled asphalt pavement (RAP) in our production processes. This not only minimizes waste but also reduces the demand for new materials, making asphalt production more sustainable.

2. Emission Control

Our asphalt batch mix plants come equipped with advanced dust and emission control systems, ensuring compliance with environmental regulations and reducing the carbon footprint of construction operations.

3. Energy Efficiency

Our innovative designs focus on energy efficiency, incorporating features that reduce energy consumption during the asphalt production process.

The Future of Asphalt Batch Mix Plants

The construction industry is evolving, and so are asphalt batch mix plants. The integration of smart technologies, the use of sustainable materials, and a focus on automation will define the future of asphalt production. As a forward-thinking asphalt batch mix plant supplier, Polygon Machinery embraces these trends and continues to innovate, ensuring our customers remain competitive in a rapidly changing market.

Conclusion

Choosing the right asphalt batch mix plant supplier can significantly impact the success of your construction projects. With Polygon Machinery, you gain access to unparalleled quality, innovative technology, and dedicated support. Our commitment to excellence and sustainability ensures that you can meet your construction goals efficiently and responsibly.

For more information on our products and services, or to discuss your specific needs, please visit our website at Polygon Machinery.